Conditions

- Bird Strikes

- Catastrophic Loss of an Engine

Sensor Requirements

- 30 mm Displacement of Engine Support Structure

- Side-Viewing Probes

- 12 m Fiberoptic Cables

- 20 KHz Sensor Bandwidth

High Speed Compressor Blade Vibration Tests

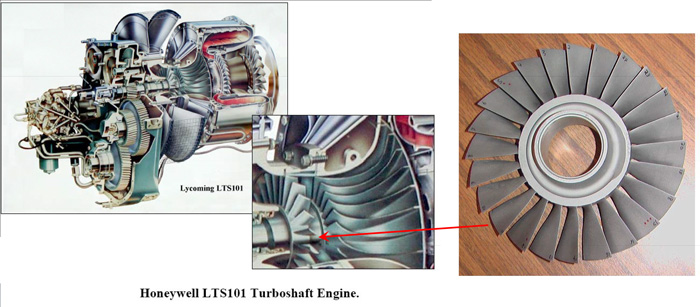

The compressor test rig uses a small axial blisk from a 2 stage LTS101 Turboshaft Engine.

- A High Speed Philtec D63 Probe was attached to the shroud and pointed radially inward at the blade tips.

- Blade vibration can be detected directly from the deviation in expected arrival time curves for each blade.