Click here to see all cable options.

Standard

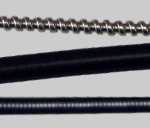

A PVC jacket over a flat steel ribbon monocoil is the standard cable jacket, which is an excellent combination for general purpose usage.

Alternatives

Interlocking Stainless Steel, Option C1, is the most popular alternative jacket, providing the highest temperature capability and maximum crush resistance with good flexibility.

Bending Radius

Fiber optic cables sometimes are routed thru and around machinery. A rule of thumb when specifying jackets:

- For Option C1, minimum bend radius is 4x the jacket OD

- Flexible jackets like C3, C8, C11, minimum bend radius could be as small as 2x OD

Vacuum

For vacuum & cryogenic applications, low outgassing materials are required. SS Interlock, PTFE and polyolefin are good choices.

Notes

- Sensors with the longest cables have 2x higher noise levels.

- Please consult the factory when combining Options B,E and/or H.

| Model | Materials | Temperature Range | Features |

|---|---|---|---|

| none | PVC over Steel Monocoil | +10 to +105 C | Good general purpose, moderate crush resistance, moderate tensile strength. |

| C1 | Interlocking Stainless Steel | -150 to +450 C | High strength & temperature range, good flexibility. |

| C2 | Silicone-Fiberglass over Steel Monocoil | -75 to +232 C | Flexible and durable, moderate crush resistance, good tensile strength, radiation resistant. |

| C3 | Silicone-Fiberglass | -75 to +232 C | Very flexible and durable, light crush resistance, good tensile strength, excellent flex life and resistance to fatigue, radiation resistant. |

| C5 | PVC over Interlocking Stainless Steel | +10 to +105 C | Excellent pliability, does not stretch, resists lateral pressure, twisting & pulling, withstands repeated bending. |

| C6 | Convoluted PTFE | -150 to +260 C | Good for vacuum applications, moderate crush resistance, very flexible, MRI compatible. Opaque PTFE is available in limited sizes. |

| C7 | PTFE | -150 to +260 C | Liquid tight vapor barrier protection, very poor flexibility. Vacuum & MRI compatible. |

| C8 | PVC | +10 to +107 C | Small lightweight, very flexible, liquid tight, MRI compatible, no crush resistance. |

| C9 | Annealed SS Tubing | -150 to +450 C | Semi-rigid, liquid tight, crush proof. Good for high temperature, high pressure, high vibration environments |

| C11 | Polyolefin Shrink Tubing | -55 to +300 C | Semi-Flexible, liquid tight, thin wall vapor barrier, not crush resistant. MRI and vacuum compatible, radiation resistant. |

| C12 | Polyolefin Over SS Interlok | -55 to +300 C | Crush proof, semi-flexible, liquid tight, thin wall vapor barrier, vacuum compatible. |

| C13 | Furcation Tubing | +10 to +85 C | PVC over Kevlar over Polypropylene fibers prevent stretching. Good for small fiber sensors, D20 or RC20 and smaller. MRI compatible and liquid tight. Light crush resistance but not kink resistant. |

| C14 | Miscellaneous | Customer choice for special application. |